Sign Up

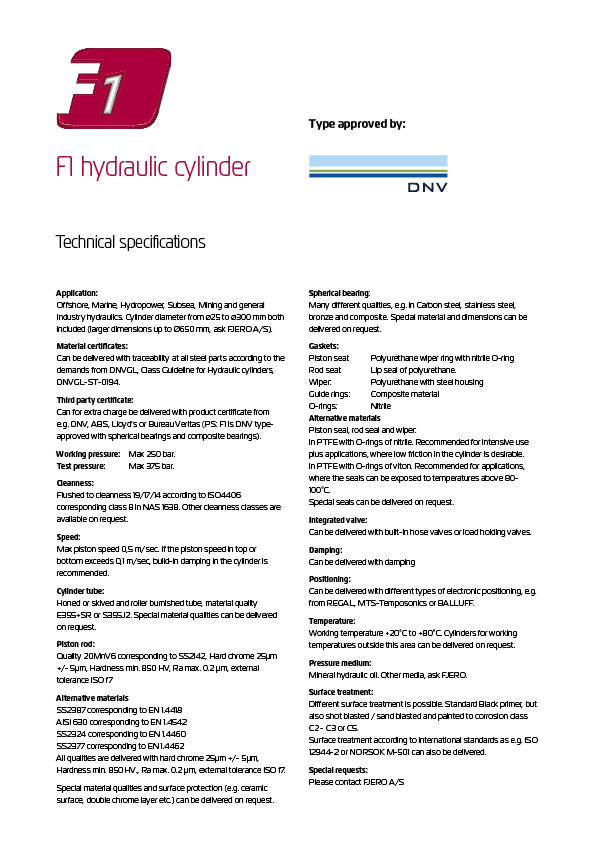

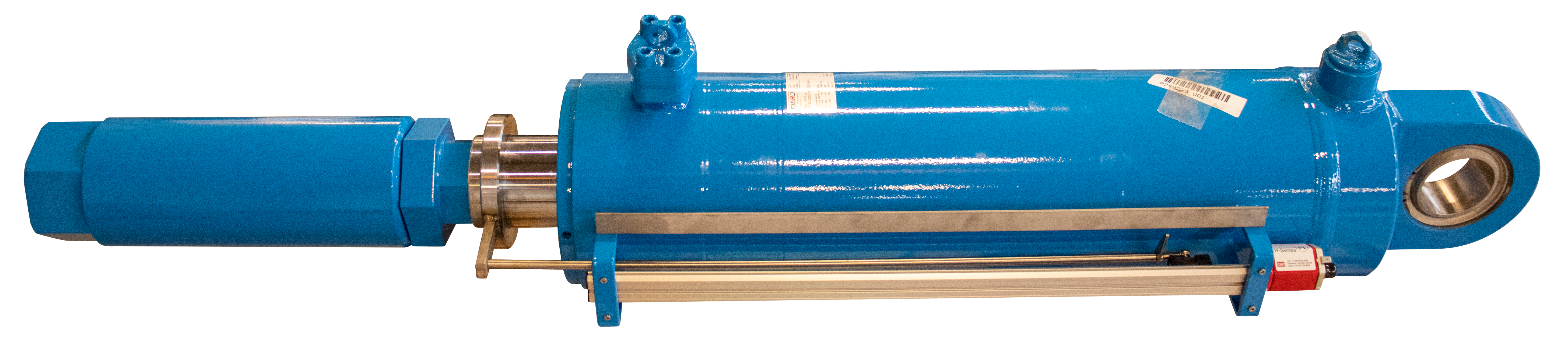

The F1 cylinder is designed and developed for companies with high requirements for traceability and documentation

.png)

F1 cylinder with standard type approval

Besides DNV.GL type approval, FJERO’s F1 cylinders can also be supplied with material certificates and pressure test certificates. The F1 cylinder is also offered with other third-party approvals, for example ABS, Lloyd’s, Bureau Veritas, RINA, CCS and many others.

The F1 cylinders are thus the natural choice for customers requiring a high degree of traceability and documentation of applied materials and functions. The F1 cylinder has been tried and tested in many different applications - in a nutshell: Proven Technology.

Option for additional functions

The F1 cylinder can be supplied with a wide range of additional functions that increase the functionality and thus the value of the cylinder.

These include:

• Integrated valves in the form of built-in hose rapture or load-holding valves.

• Dampening at top and bottom when piston speed is above 0.5 m/sec.

• Different types of electronic positioning, e.g. from MTS-Temposonics, BALLUF or REGAL.

• Etc.

.png)

Customer wishes accommodated

All special customer wishes can be accommodated according to the task requirements. Regardless of whether they apply to the choice of material for cylinder tubes, special types of housing, selected seals or other wishes, FJERO can adapt the design. This also applies to special surface treatments. FJERO’s cylinders come coated with black primer as standard, but can also be supplied as sandblasted and painted to corrosion classes C2, C3 or C5. FJERO can supply surface treatments in accordance with international standards such as ISO 12944-2 or NORSOK M-501.

If you DON’T require traceability or documentation, please refer to our F2 cylinder.